The Hydraulic Molding Machine For Polystyrene Or EPS Or EPC

description2

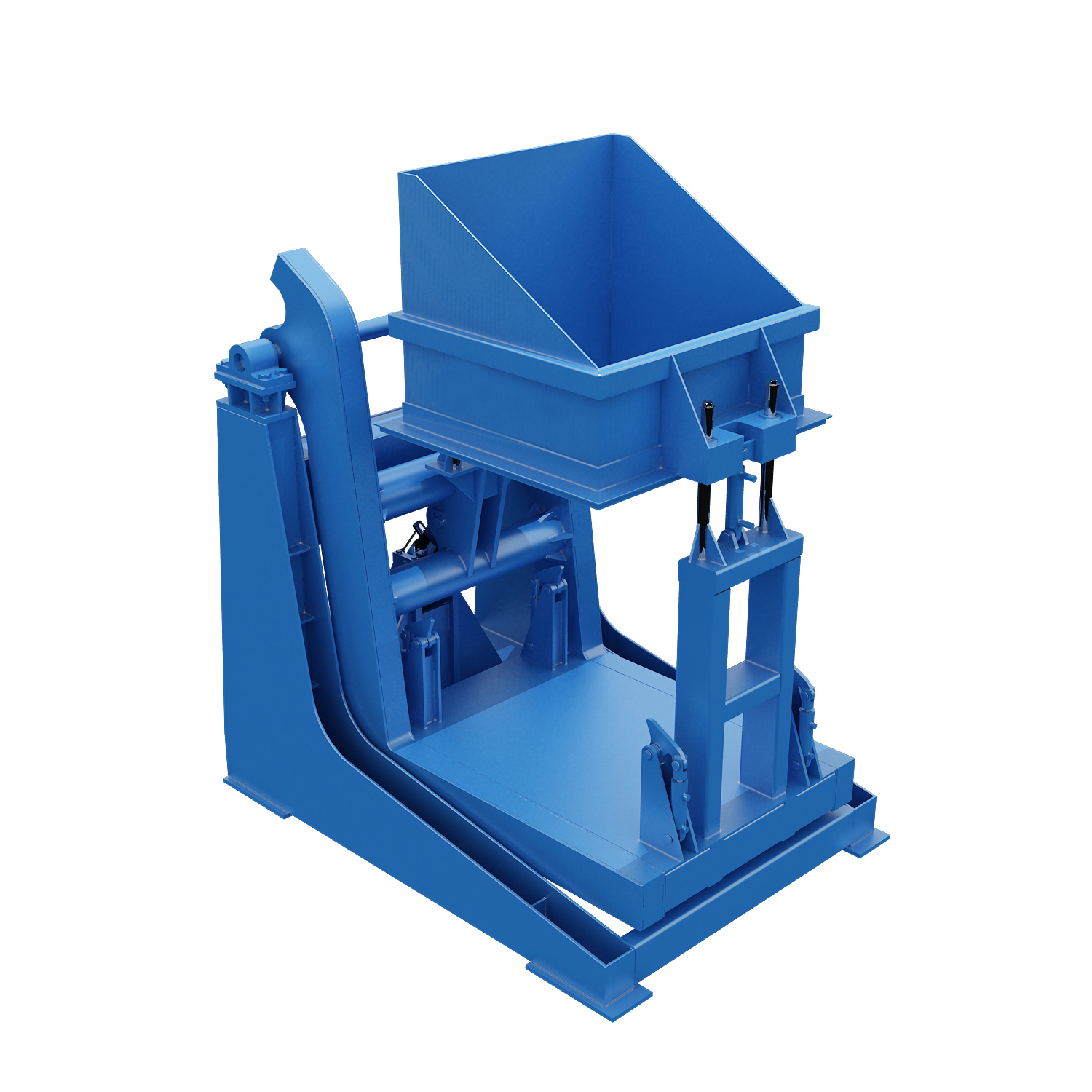

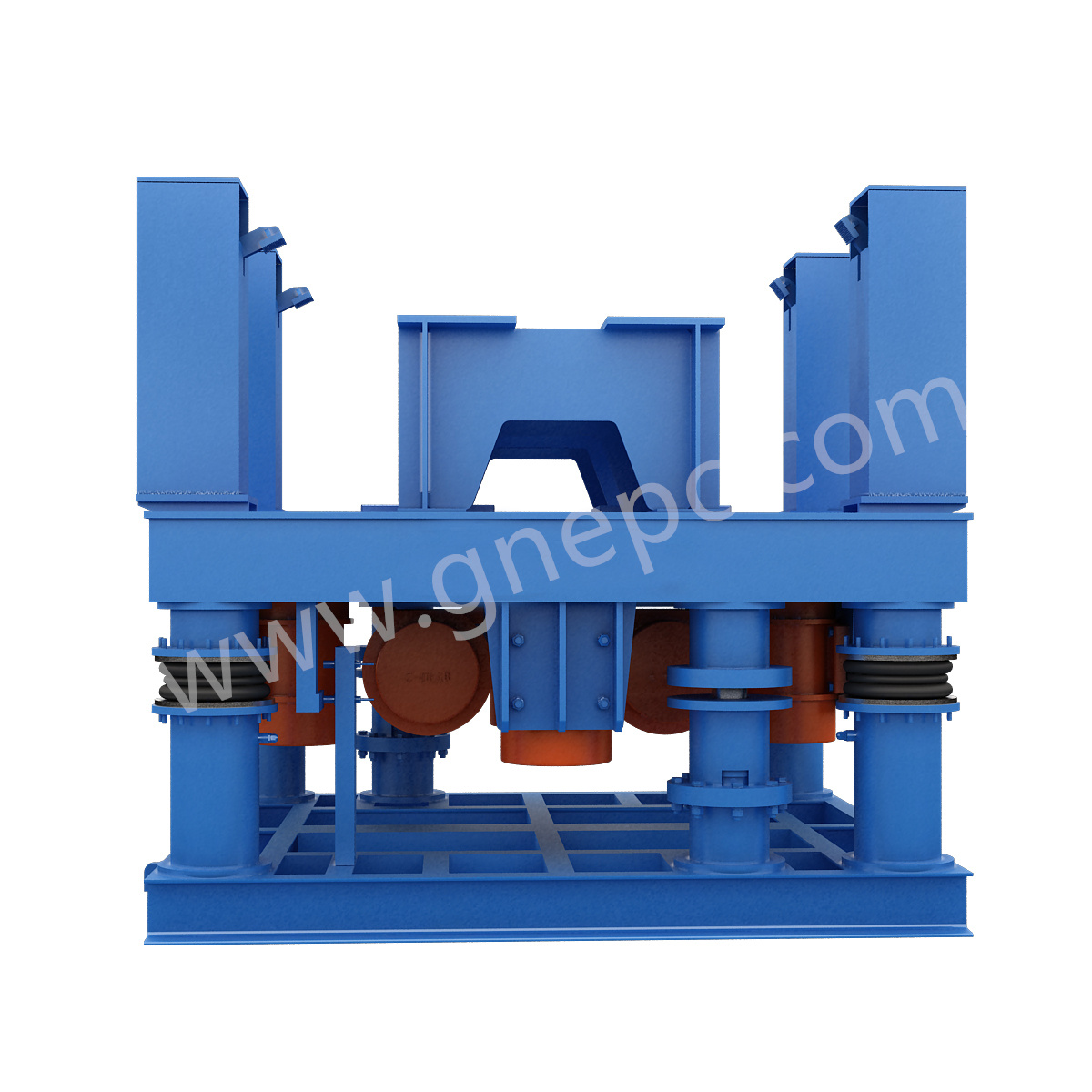

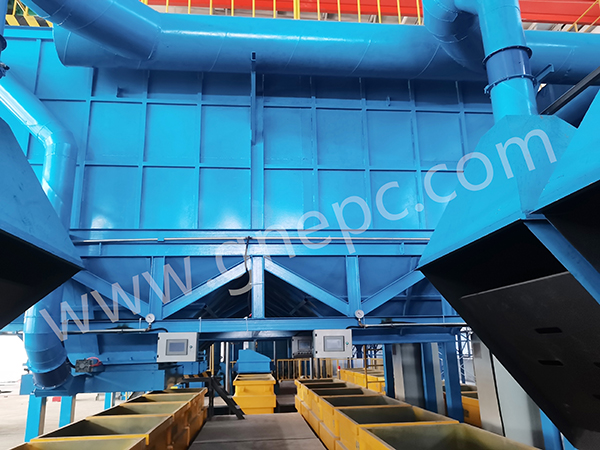

product display

Main technical parameters

no. |

name |

unit |

ROCX-Ⅱ(01) |

ROCX-Ⅱ(02) |

ROCX-Ⅱ(02) |

ROCX-Ⅱ(03) |

ROCX-Ⅱ(04) |

ROCX-Ⅱ(03) |

|

1 |

table size |

mm |

1200*1000 |

1500*1200 |

1500*1500 |

1800*1500 |

1800*1800 |

2800*2200 |

|

2 |

standard effective travel (can be requested) |

m |

1.0m |

1.5m |

1.5m |

1.5 m |

1.5 m |

1.8m |

|

3 |

minimum distance between moving and fixed molds |

mm |

100mm |

100mm |

100mm |

100mm |

100mm |

100mm |

|

|

4

|

guide pillar

|

outside diameter |

mm |

φ65mm |

φ65mm |

φ65mm |

Φ70mm |

Φ70mm |

φ75mm |

quantity |

count |

4 |

4 |

4 |

4 |

4 |

4 |

||

5 |

hydro-cylinder |

diameter |

mm |

Φ100*1 |

Φ100*2 |

Φ100*2 |

Φ125*2 |

Φ125*2 |

Φ125*4 |

6 |

maximum speed of moving mold operation |

mm/s |

190 |

190 |

190 |

190 |

190 |

190 |

|

|

7

|

steam system

|

main entrance |

inch |

1" |

1" |

1" |

1" |

1" |

1" |

mold inlet |

inch*qty |

1"×2 |

1"×2 |

1"×2 |

1"×3 |

1"×3 |

1"×4 |

||

working pressure |

MPa |

0.3~0.6 |

0.3~0.6 |

0.3~0.6 |

0.3~0.6 |

0.3~0.6 |

0.3~0.6 |

||

consumption |

kg/cycle |

3~6 |

3~3.75 |

3~3.75 |

6~9 |

6~9 |

8~12 |

||

|

8

|

cooling water system

|

main entrance |

inch |

1" |

1" |

1" |

1" |

1" |

1" |

mold inlet |

inch*qty |

1"×2 |

1"×2 |

1"×2 |

1"×2 |

1"×2 |

1"×3 |

||

working pressure |

MPa |

0.4~0.5 |

0.4~0.5 |

0.4~0.5 |

0.4~0.5 |

0.4~0.5 |

0.4~0.5 |

||

consumption |

kg/cycle |

25~70 |

25~70 |

40~90 |

40~90 |

40~90 |

40~90 |

||

temp |

℃ |

20~45 |

20~45 |

20~45 |

20~45 |

20~45 |

20~45 |

||

|

9

|

compressed gas

|

main entrance |

吋 |

1" |

1" |

1" |

1" |

1" |

1" |

working pressure |

MPa |

0.6~0.8 |

0.6~0.8 |

0.6~0.8 |

0.6~0.8 |

0.6~0.8 |

0.6~0.8 |

||

consumption |

m3/cycle |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

||

10 |

sewage system |

pipe diameter |

inch*qty |

2"×2 |

2"×2 |

2"×2 |

2"×2 |

2"×2 |

2"×2 |

11 |

electric motor |

|

kw/rpm |

4KW |

5.5KW |

5.5KW |

7.5KW |

7.5KW |

5.5KW |

12 |

fuel tank capacity |

L |

|

200 |

240 |

240 |

240 |

240 |

240 |

13 |

forming time |

s/cycle |

90~180 |

90~180 |

90~180 |

90~180 |

90~180 |

90~180 |

|

Product performance and features detailed product introduction

This product is a specialized hydraulic forming machine for lost foam molding, which adopts computer control and has relatively improved automation level.

The rapid opening and closing speed of the machine is more than three times faster than that of the worm gear and screw pair transmission, with advantages such as fast speed, accurate seam reservation, high production efficiency, and convenient operation.

The equipment advantage

Lost foam casting has made significant progress in both process technology and equipment optimization since its rise in China in the early 1990s. A large number of manufacturers of lost foam casting equipment have emerged in the market, among which there are some equipment manufacturing enterprises who take lost foam casting technology too simplistic. They know it, but do not know why. They use simple packaging equipment in the market to make lost foam white molds, causing various problems such as surface defects, deformation, insufficient strength, insufficient filling, and size deviation of the white molds.

Specific properties are as follows:

- Unique bead filling system (German technology, pulse feeding) - full bead filling and smooth surface.

- Unique material gun - quickly filling beads into various parts of the model cavity in multiple directions.

- Computer operation software - software developed specifically for the lost foam process based on computer screens and PLC automatic control.

- Unique high-pressure pulse feeding process - ensuring that the white molds of various complex structures are full and not deformed.

- Improve production efficiency - The perfect combination of various systems of the entire machine results in high production efficiency.

Performance characteristics

The template of this machine adopts artificially aged steel plates and four quenched and tempered guide pillars, forming a rigid frame, high strength, and corrosion resistance.

The transmission adopts hydraulic cylinder differential mode.

Electrical appliances, pneumatic components, and valves are well-known brands both domestically and internationally, with stable and reliable operation and long service life.

Adopting PLC programmable controller and touch screen control, automatically completing a molding process.

Using a digital encoder to control the clamping size, the module deviation is small, and the white mold is smooth, ensuring the subsequent process is carried out.