0102030405

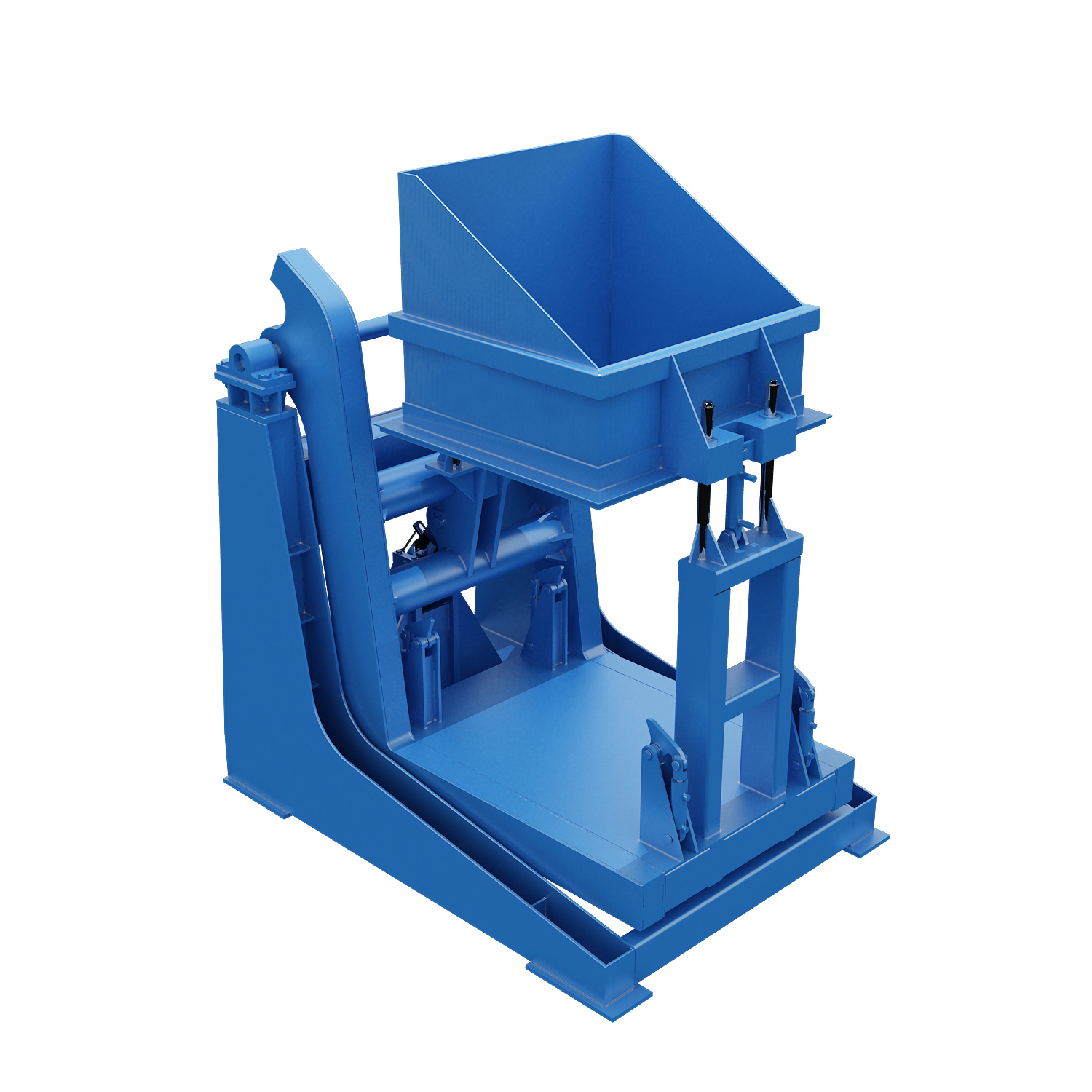

Sand box

description2

Equipment technical parameters

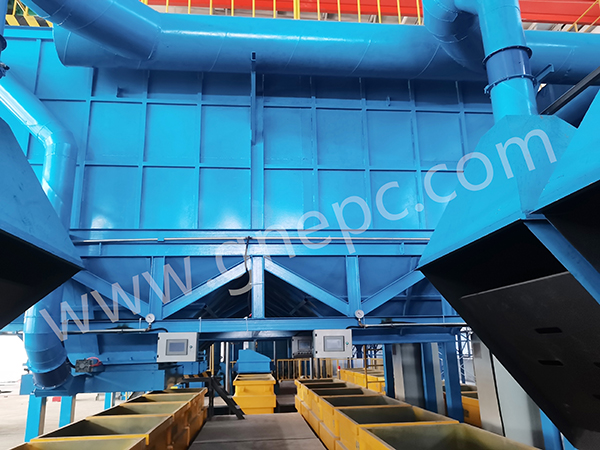

①Inner net size: 3200×2500×2000mm;

②Screen: 60 mesh stainless steel, (304 stainless steel) screen;

③The side plate is made of 6mm steel plate, and the bottom plate is made of 10mm steel plate. The overall bending and welding are formed, and the external frame is reinforced with square tubes;

④The top shaft with adjustable sand box length at both ends of the box

⑤The walking wheel is quenched with 45 # steel, with a diameter of 130mm * 4 wheels.

Product structure

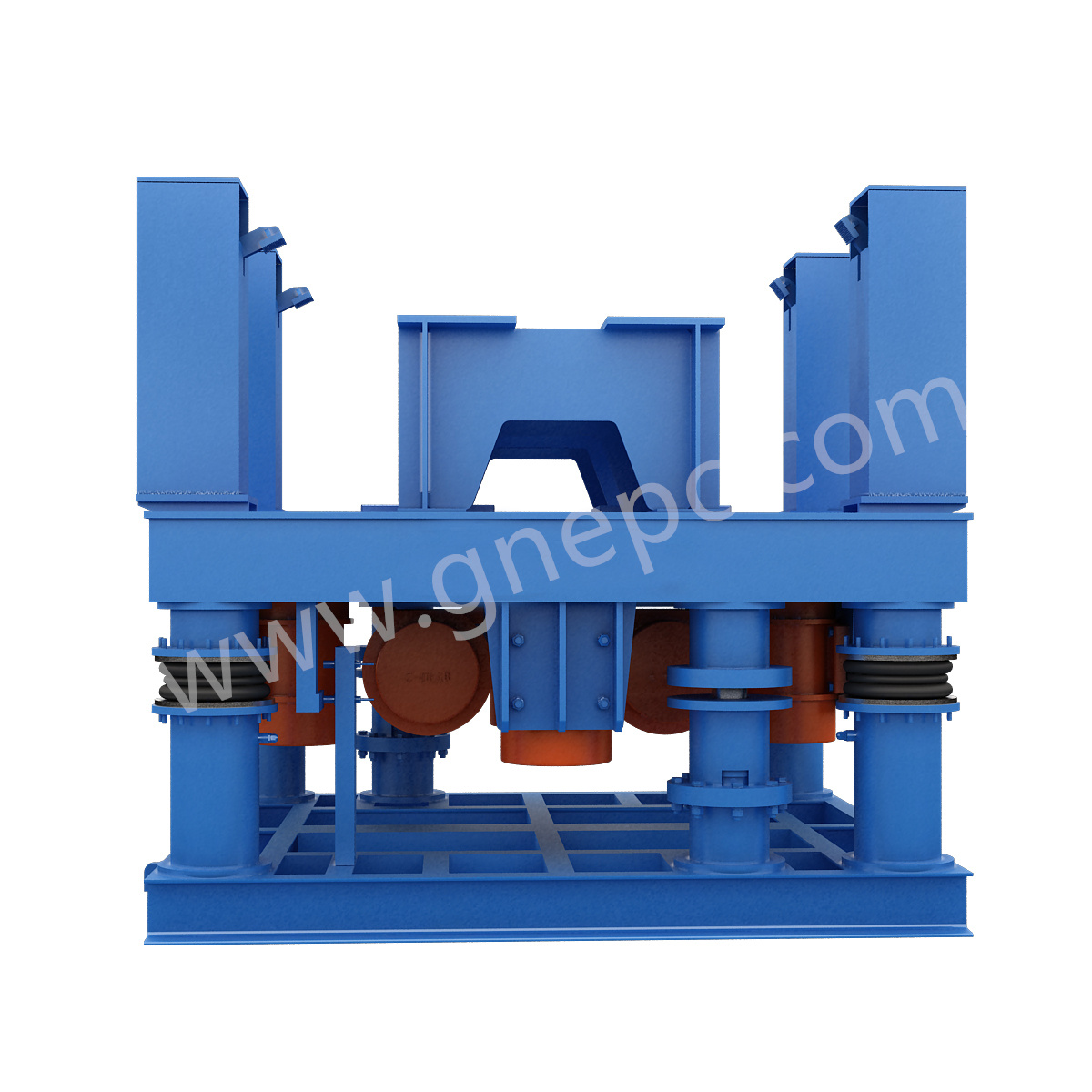

The sand box is mainly composed of the sand box body, flange, lifting eye, negative pressure port, top shaft, walking wheel, back blowing device, etc.

The two top axles are adjustable, and the sand box wheel must ensure that all four wheels are on the ground. The distance between the wheels and the parallelism of the wheels must be strictly controlled to not exceed ± 1mm to prevent the three wheels from landing and increase the pushing resistance. Ensure the flatness of the sand box bottom plate.

Main functions and advantages

①The internal air chamber of the box is divided into two groups of areas, located at the bottom of the box and around the box, with reasonable distribution to ensure a reasonable negative pressure field is achieved inside the box during pouring and vacuum pumping, ensuring good casting molding and avoiding defects. At the same time, the internal air duct structure also plays a role in strengthening the strength of the box. There are no air chambers at the corners of the bent sand box, but the air chambers on the box are wider than those on ordinary sand boxes.

②Double sided welding is used between the boards of the sand box body, with tight welds to ensure the airtightness of the air chamber.

③The walking wheel is quenched with 45 # steel.