International Development Trends of Lost Foam Casting

2024-05-02 17:30:49

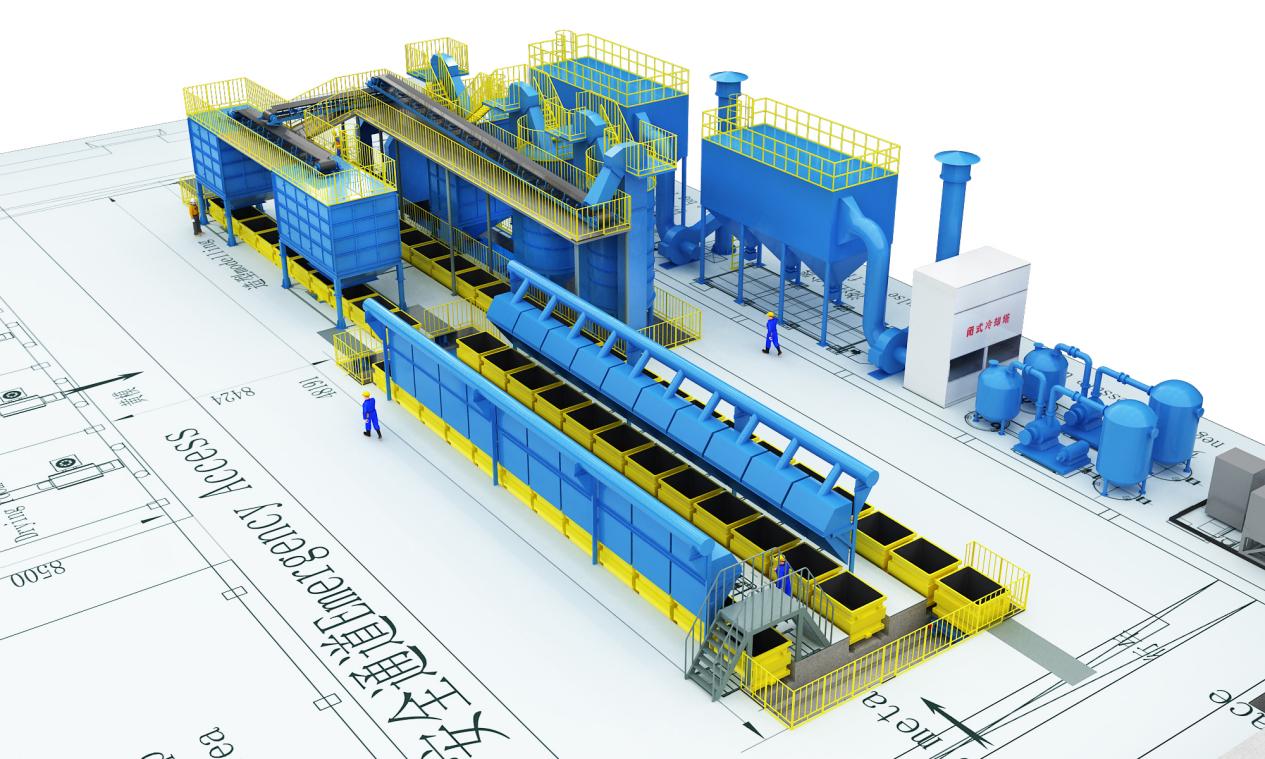

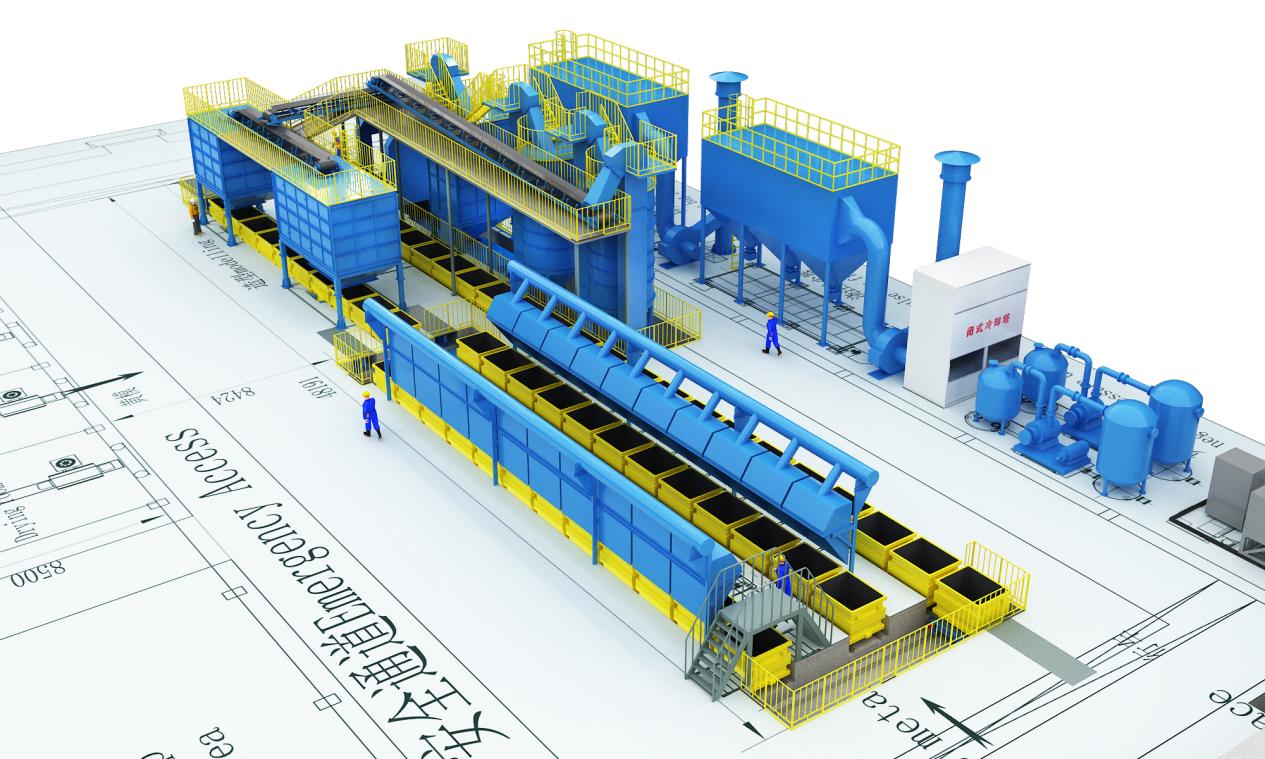

Lost foam casting is a modern casting process that has gained significant attention in the manufacturing industry. This innovative technique involves creating a foam model of the desired part, coating it with a refractory material, and then pouring molten metal into the mold to create the final product. The foam model is then vaporized by the molten metal, leaving behind a precise and intricate casting. This method has been widely adopted in various industries due to its numerous advantages, including cost-effectiveness, design flexibility, and minimal material waste.

In recent news, the lost foam casting process has been making headlines for its growing popularity and its potential to revolutionize the manufacturing sector. With the increasing demand for complex and lightweight components in industries such as automotive, aerospace, and energy, lost foam casting has emerged as a viable solution for producing intricate and high-quality parts.

One of the key international development trends of lost foam casting is its application in the production of lightweight components for the automotive industry. With the global push towards reducing vehicle weight to improve fuel efficiency and reduce emissions, automakers are turning to advanced casting techniques like lost foam casting to manufacture lightweight and durable parts. This trend is expected to continue as the automotive industry seeks to meet stringent environmental regulations and consumer demands for more fuel-efficient vehicles.

Another significant trend in the international development of lost foam casting is its adoption in the aerospace industry. The aerospace sector requires components that are not only lightweight but also have high strength and precision. Lost foam casting offers the ability to produce complex aerospace components with intricate geometries and thin walls, making it an attractive option for aerospace manufacturers. As the demand for air travel continues to rise, the aerospace industry is looking to advanced casting processes like lost foam casting to meet the growing need for lightweight and high-performance parts.

Furthermore, the energy sector is also embracing lost foam casting for the production of components used in power generation and renewable energy systems. The ability of lost foam casting to create intricate and near-net-shape parts makes it an ideal choice for manufacturing components such as turbine blades, impellers, and heat exchangers. As the global demand for energy continues to increase, the adoption of lost foam casting in the energy sector is expected to grow, driven by the need for efficient and reliable components in power generation and renewable energy applications.