Negative pressure distributor

description2

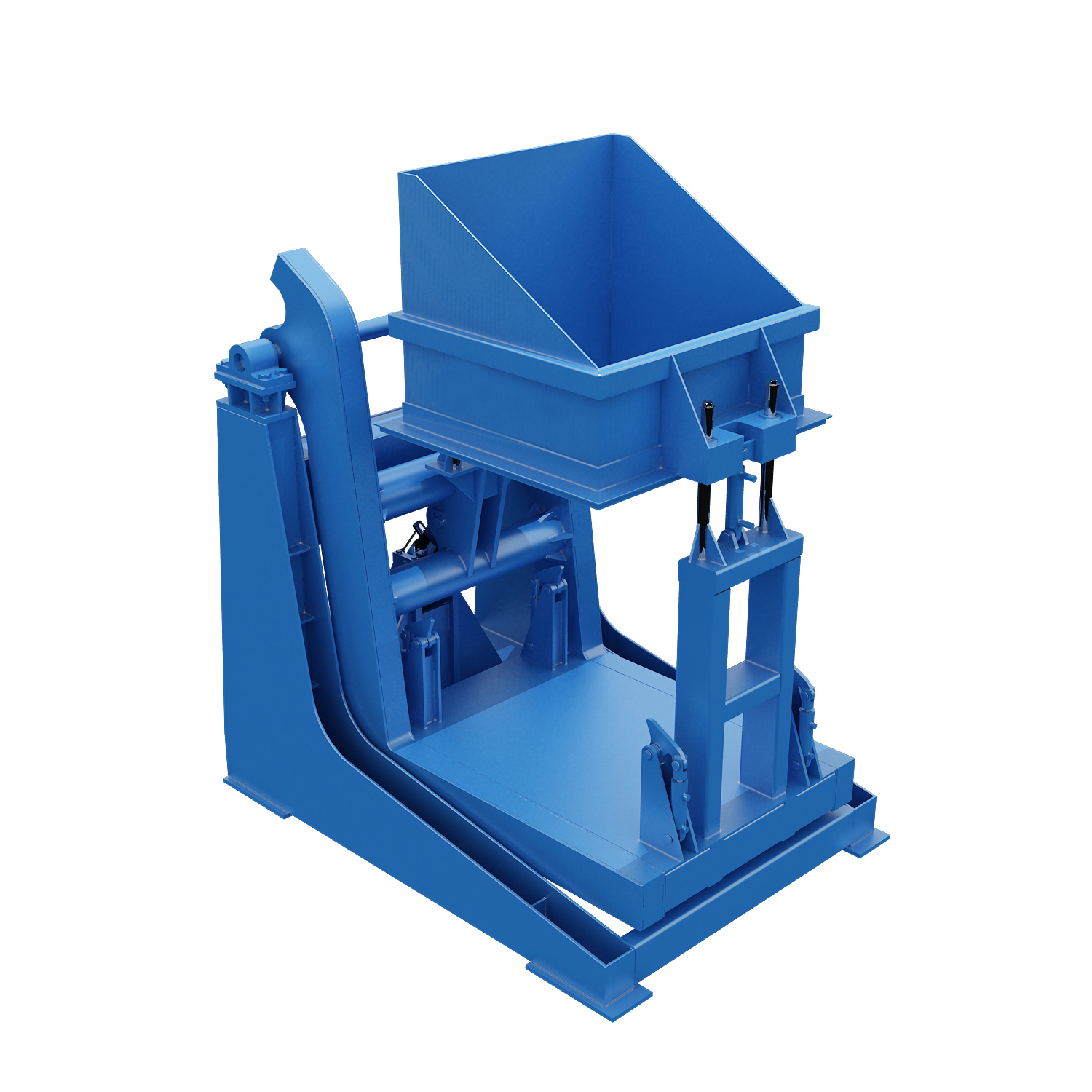

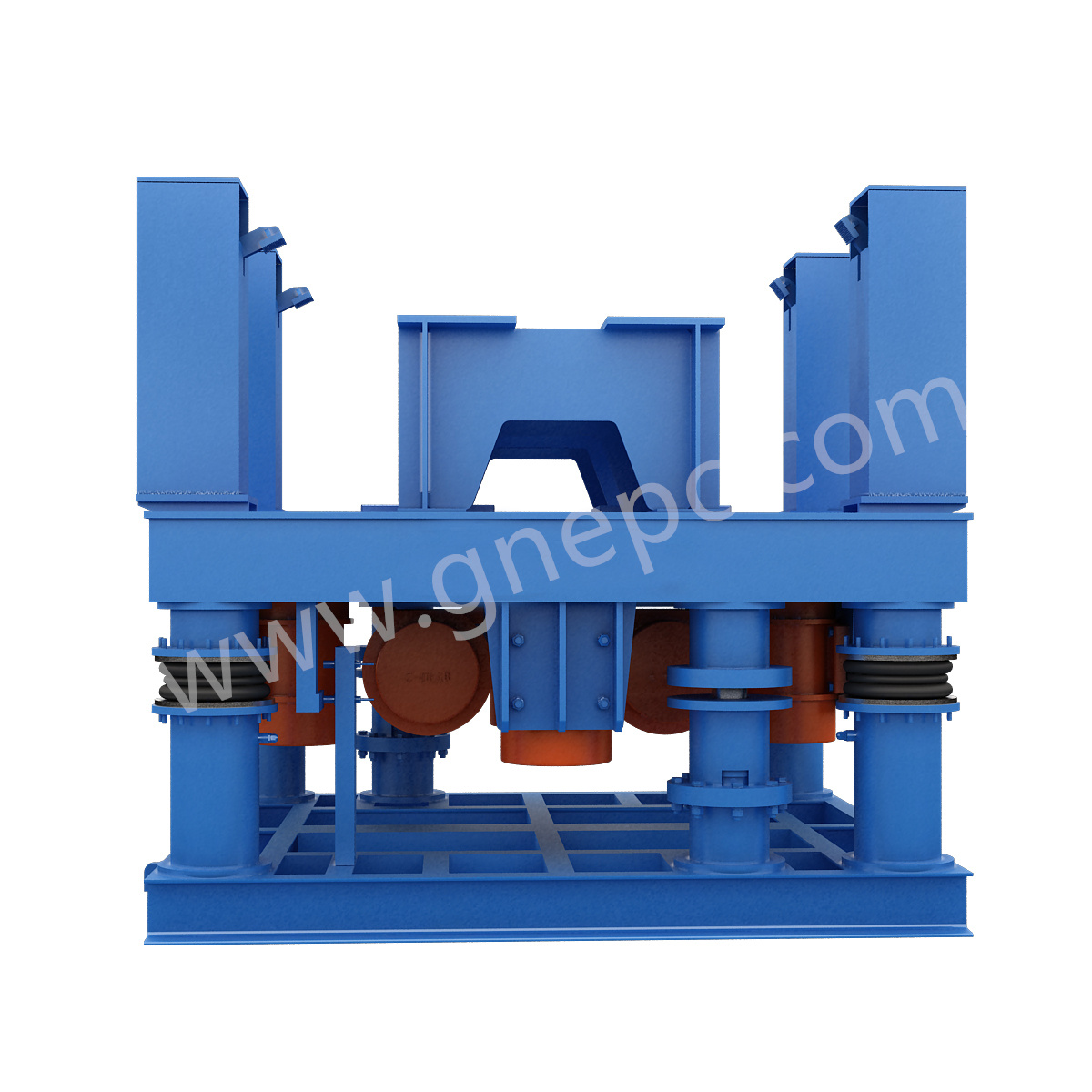

product display

Main technical parameters

①Side Pull/Bottom Pull;

②Telescopic cylinder model: SC-80 × 125-S-LB with magnetic ring;

③The internal pipe size is φ 108mm;

④The docking block is made of 30mm thick high-temperature resistant silicone, with a relatively soft hardness and good sealing performance of the docking sand box;

⑤The docking stroke is 100mm;

⑥Pneumatic butterfly valve valve control;

⑦Overall size: 1100 × 300× 1250, specifically determined based on the negative pressure port of the sand box and the foundation.

Product Structure

①Equipment framework;

②Docking device (including docking blocks and cylinders);

③Pneumatic butterfly valve;

④Black rubber tube;

⑤Negative pressure distributor.

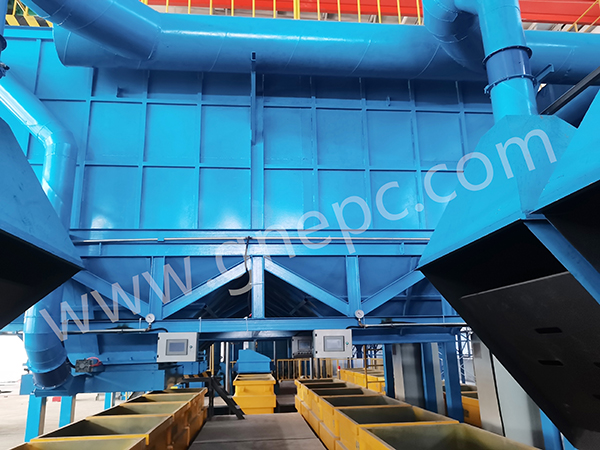

Main functions and advantages

①Function: Connect the negative pressure pipeline to the docking of the sand box (including telescopic guide sleeve).

②Connection method: By controlling the cylinder, the negative pressure system is connected to the sand box. The two systems of full pressure pouring and pressure maintaining after pouring are well connected, and each box can achieve automatic switching.

③The automatic docking device solves the problems of high labor intensity, low efficiency, and insecurity in manually connecting negative pressure pipelines and sand boxes for docking and separation.

④Adopting a structural form that ensures reliable fastening while docking. This docking device can quickly and effectively implement pipeline docking, and there is no air leakage after connection.