0102

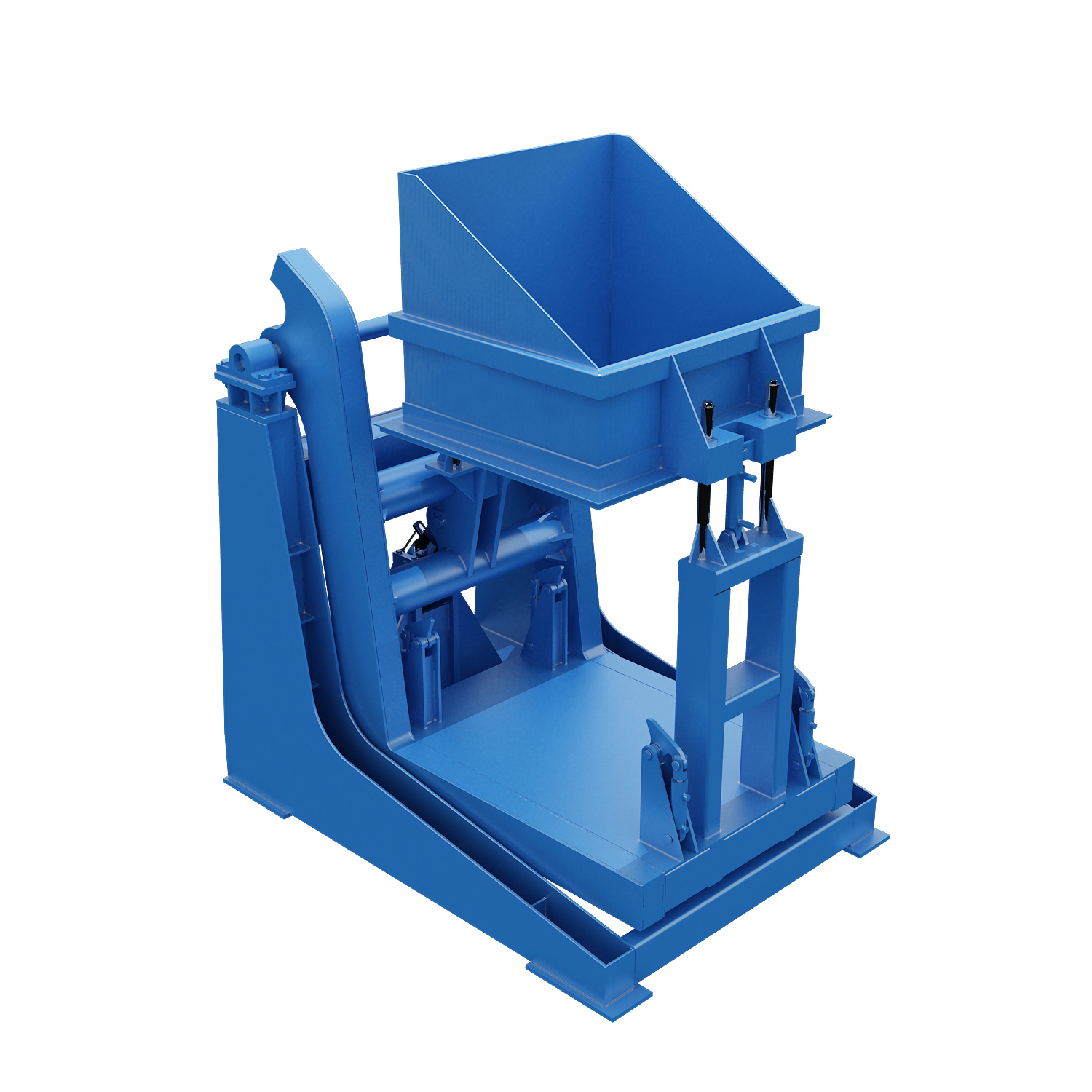

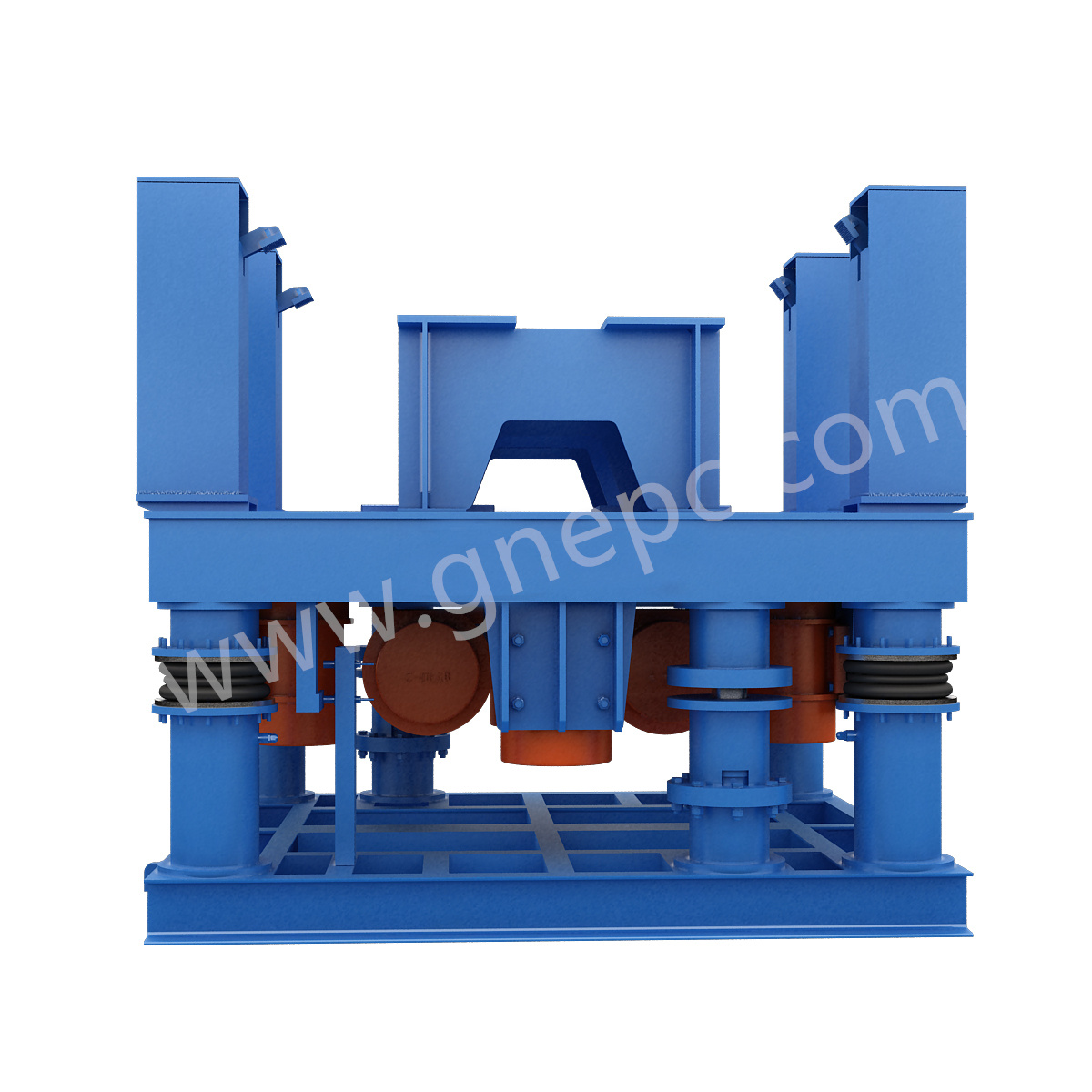

Fixed vibration table

description2

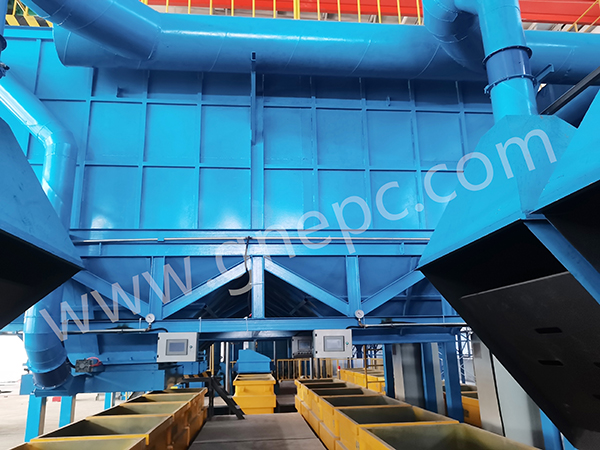

product display

Main technical parameters

- ①Platform size:1800×1500×800/ 1300×1300×800/ 1500×1500×800/ 2000×2000×1200/ 2500×2500×1200/ 3500×3000×1000mm;

-

②3 sets for vibration motors;Bottom vibration motor unit: 2 MV30-2 motors, maximum excitation force: 20KN, power: 2KW;

- Side vibration motor group 1:2 MV15-2 motors, maximum excitation force: 10KN, power: 1.3KW;

- Side vibration motor group 2: 2 MV15-2 motors, maximum excitation force: 10KN, power: 1.3KW;

- General parameters of MV series vibration motors:

- ①Rated voltage: 380V;

- ②Rated frequency: 50HZ;

- ③Motor insulation level: F Protection level: IP55;

- ④Motor phase number: 3, rated: continuous;

- ⑤Environmental temperature: -20~+40 ℃;

- ⑥Bearing grease: Shell No. 3 lithium based grease.

Product structure

①Main body of seismic consolidation station: 1 unit;

②Bottom vibration motor set: 2 side vibration motor sets 1:2 side vibration motor sets 2:2;

③Damping rubber pads: 4 pieces.

Main functions and advantages

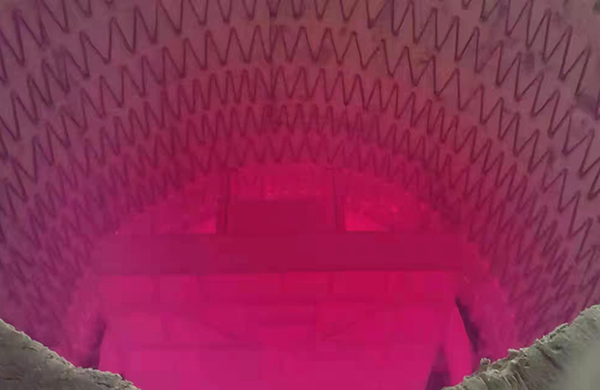

①Function: To achieve the vibration function of the model in the sand box in the lost foam process. It is an indispensable part of the lost foam casting process.

②The motor is protected by a thermal relay protector.

③The motor can adjust the excitation force by adjusting the eccentric block and frequency conversion.

④3D compaction, good compaction effect, high production efficiency, simple operation, and easy maintenance.

⑤The vibration table is treated with annealing process to eliminate welding internal stress.