01020304

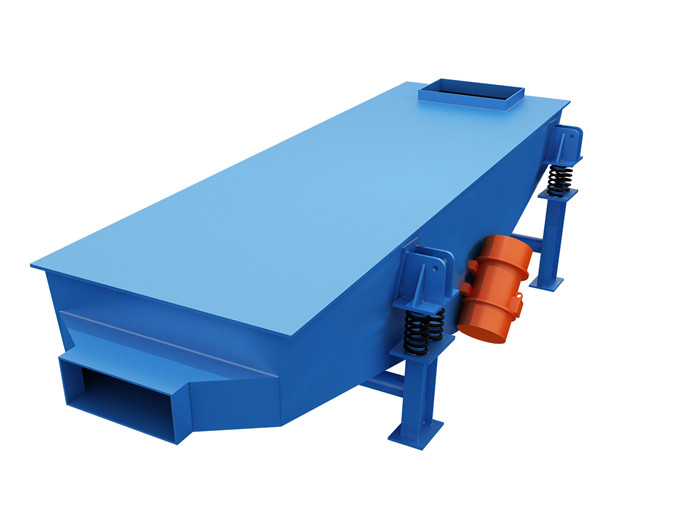

Fine screen screening conveyor

description2

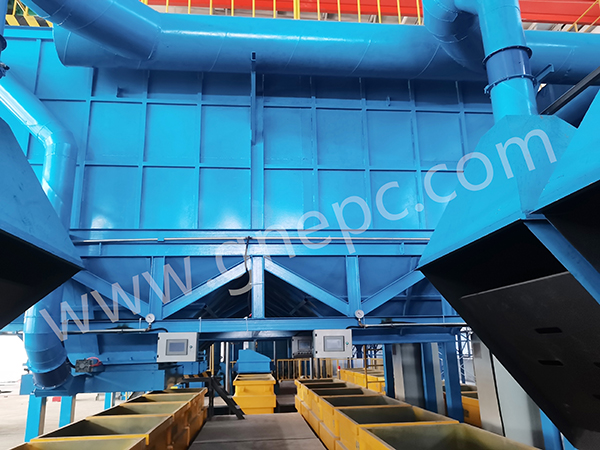

product display

Main technical parameters

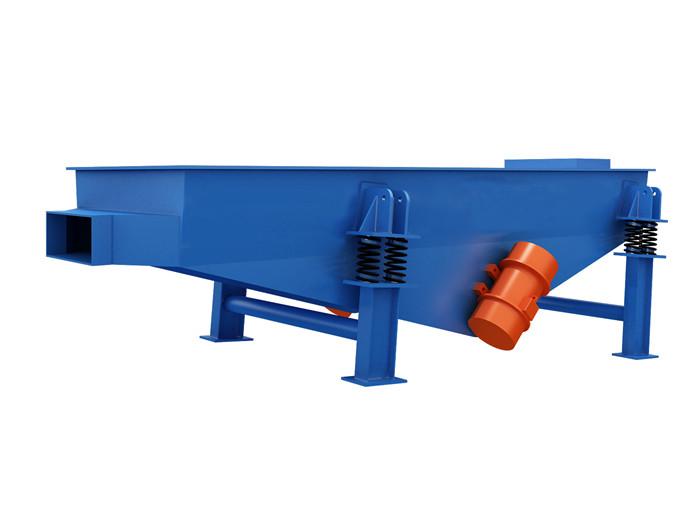

- Sand processing capacity 60T/H (20-40 mesh quartz sand);

- Overall dimensions: 2000×1100×1000 /3200/4000×1000×1000/ 4000×1300×1200 / 4000×1500×1200mm;

- Equipment power: 3KW * 2;

- Sieve plate material: stainless steel (frame 304 stainless steel);

- Sieve plate mesh: 50 mesh (fine screen).

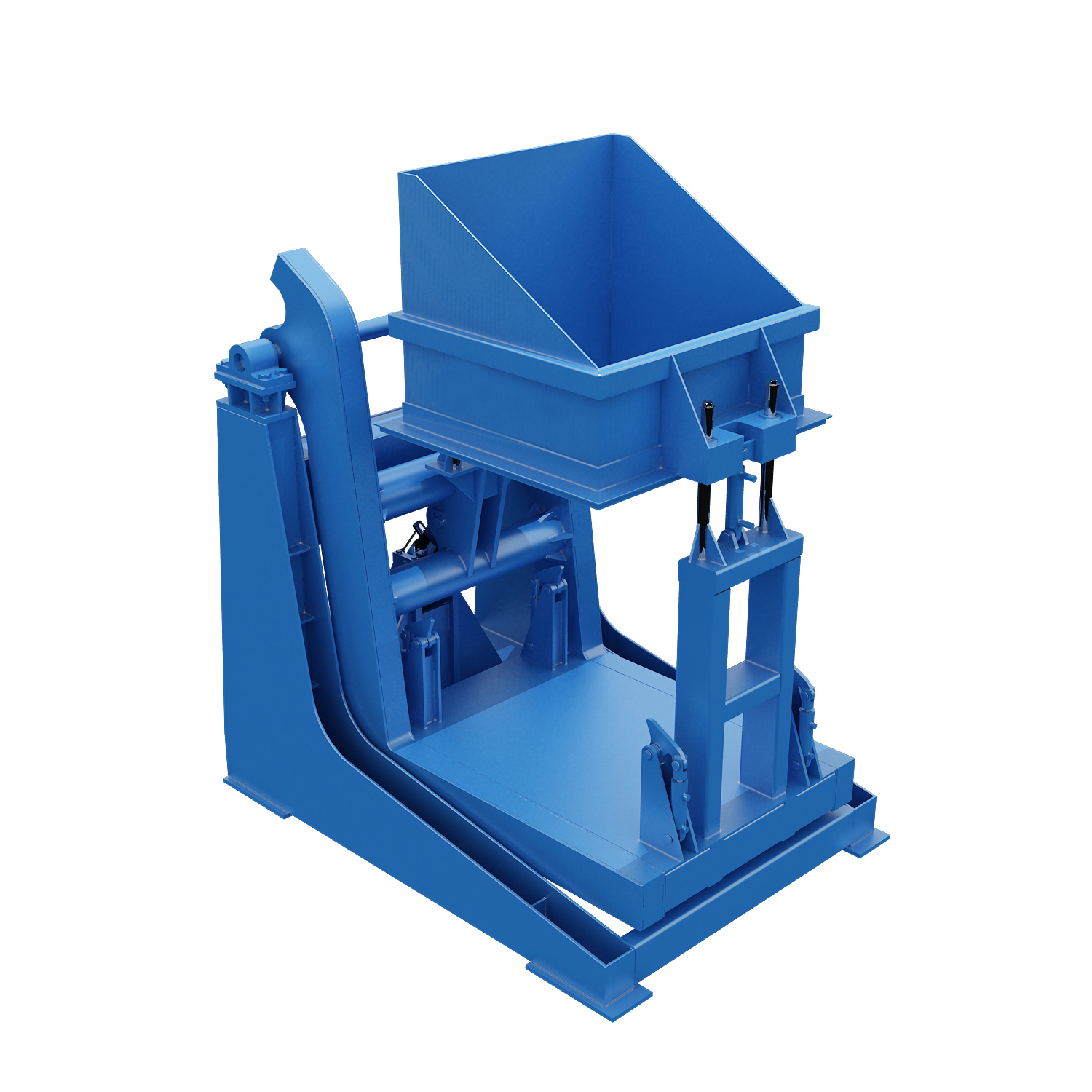

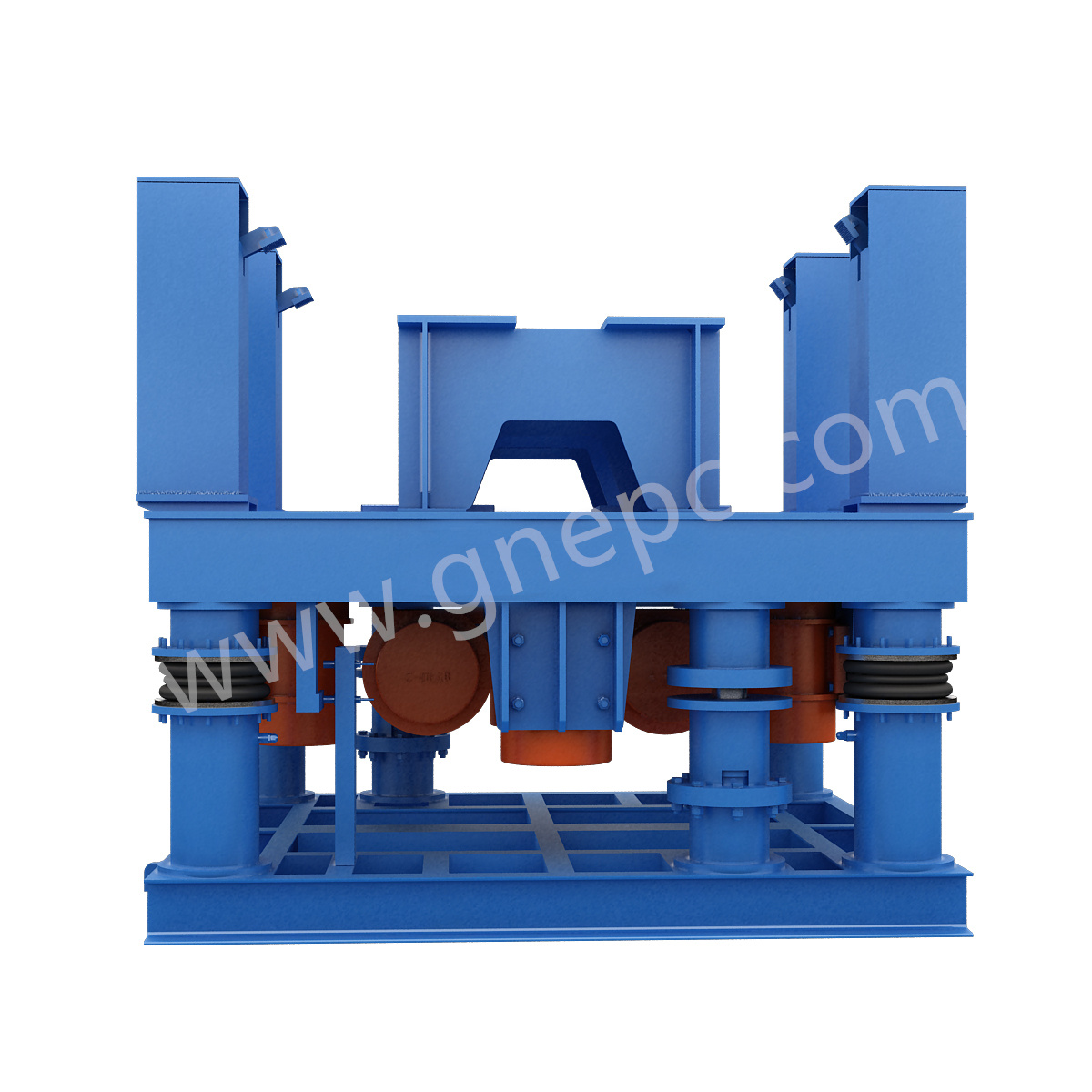

Product structure

The screening conveyor consists of the main body, base, and spring of the screening conveyor( Φ 90 * 110). Vibration motor composition.

Main functions and advantages

Screening and conveying function: The screening conveyor is used to screen the powder in old sand.

Cooling function: The material sieve has a long flowing line, which can quickly and efficiently reduce the temperature of the molding sand. It is an efficient and energy-saving sand screening equipment developed by our factory specifically for the production of dry sand negative pressure casting.

It has the characteristics of reliable structure, strong excitation force, high screening efficiency, low vibration noise, durability, convenient maintenance, and safe use.

One of the key features of this screening conveyor is its versatile motor position, which can be assembled from the top, bottom, or side. This flexibility makes it easier to integrate the conveyor into your existing setup, saving you time and effort during installation.

Screening and conveying function: The screening conveyor is used to screen the sintered coating fragments, iron beans, and other impurities in the old sand.

Cooling function: screening flow line length, 5000m ³/ The high air volume fan quickly removes heat from the hot sand through a fish scale mesh plate, which can quickly and efficiently reduce the temperature of the molding sand. It is an efficient and energy-saving sand screening and cooling equipment developed by our factory specifically for the production of lost foam casting.

It has the characteristics of reliable structure, strong excitation force, high screening efficiency, low vibration noise, durability, convenient