01

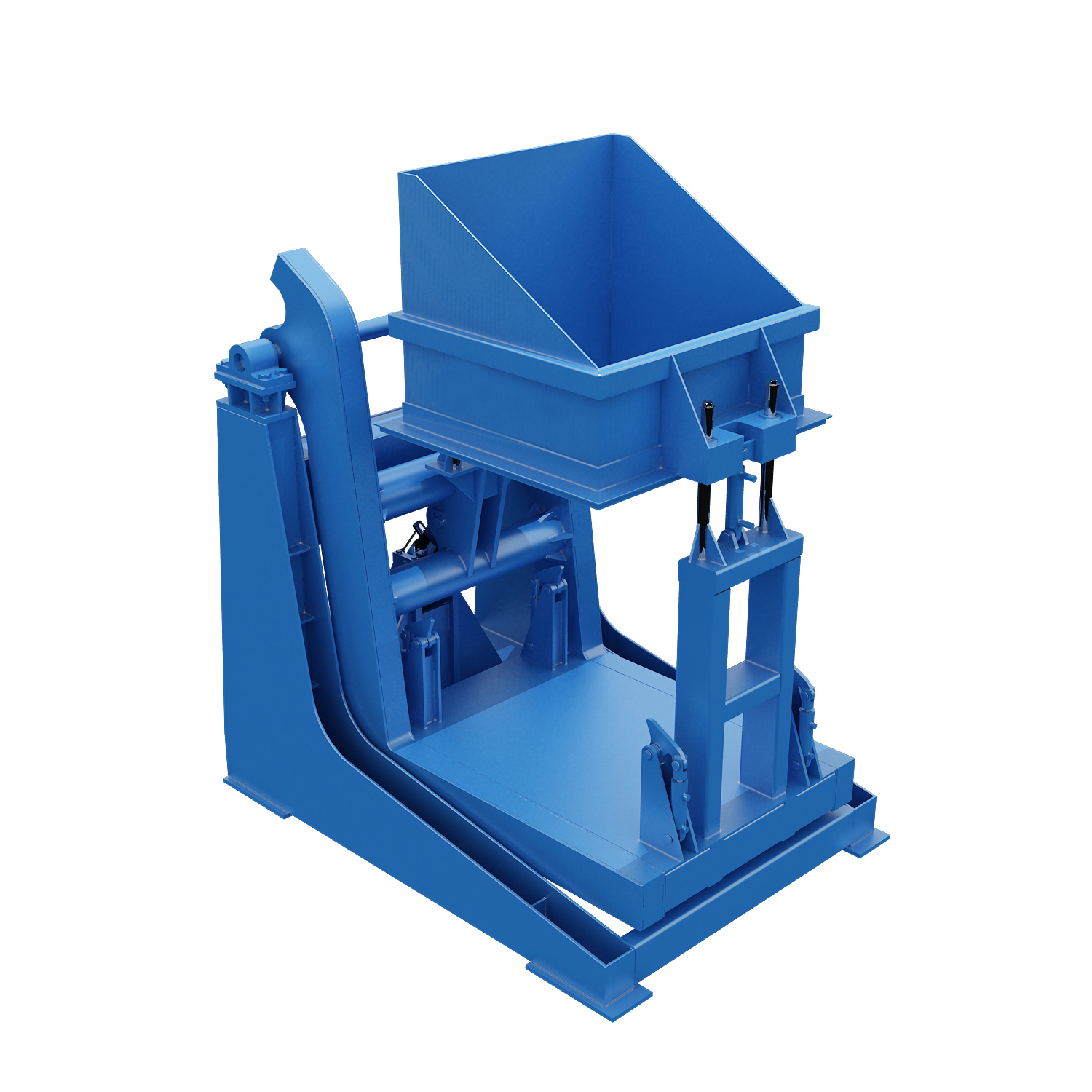

Encircling molding machine

description2

product display

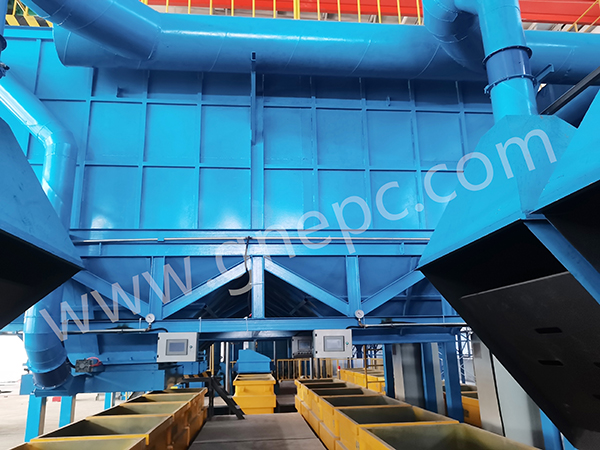

Application

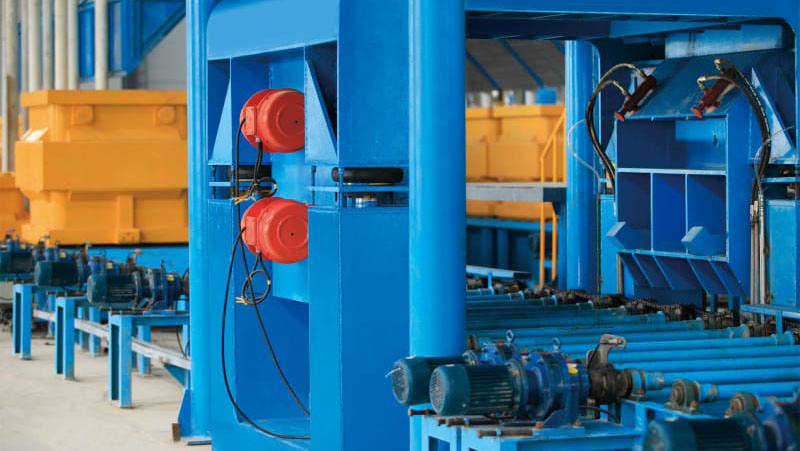

Four independent permanent magnet servo vibration motors and their driving control system can satisfy the user to realize the fast switching of three-dimensional vibration, which can shorten the vibration time and improve the vibration efficiency.the casting sand in the sand box can flow in many directions, and the cavity is preferentially filled.

Servo vibration motor feedback signal to the servo drive system, servo drive system according to the feedback value and the target, the value of comparison, adjust the rotor rotation angle, thus changing the eccentric block phase angle. The encoder is installed in the motor and has the advantages of vibration resistance and convenient processing and assembly.

According to customer product vibrating formula, vibrating formula design is based on the product structure of multi-step sand, according to the actual structure ofthe product at the height, select the appropriate 1) seismic vector (control the directionof sand movement, including: Horizontal, vertical and angle)and 2) motor speed(control the magnitude of seismic strength)to move the sand along the specificdirection to fill all the corners inside and outside the yellow mold and obtain a certaindegree of compactness.

The main technical parameters

Load: 6 tons,Specification:1500*1200*2000mm

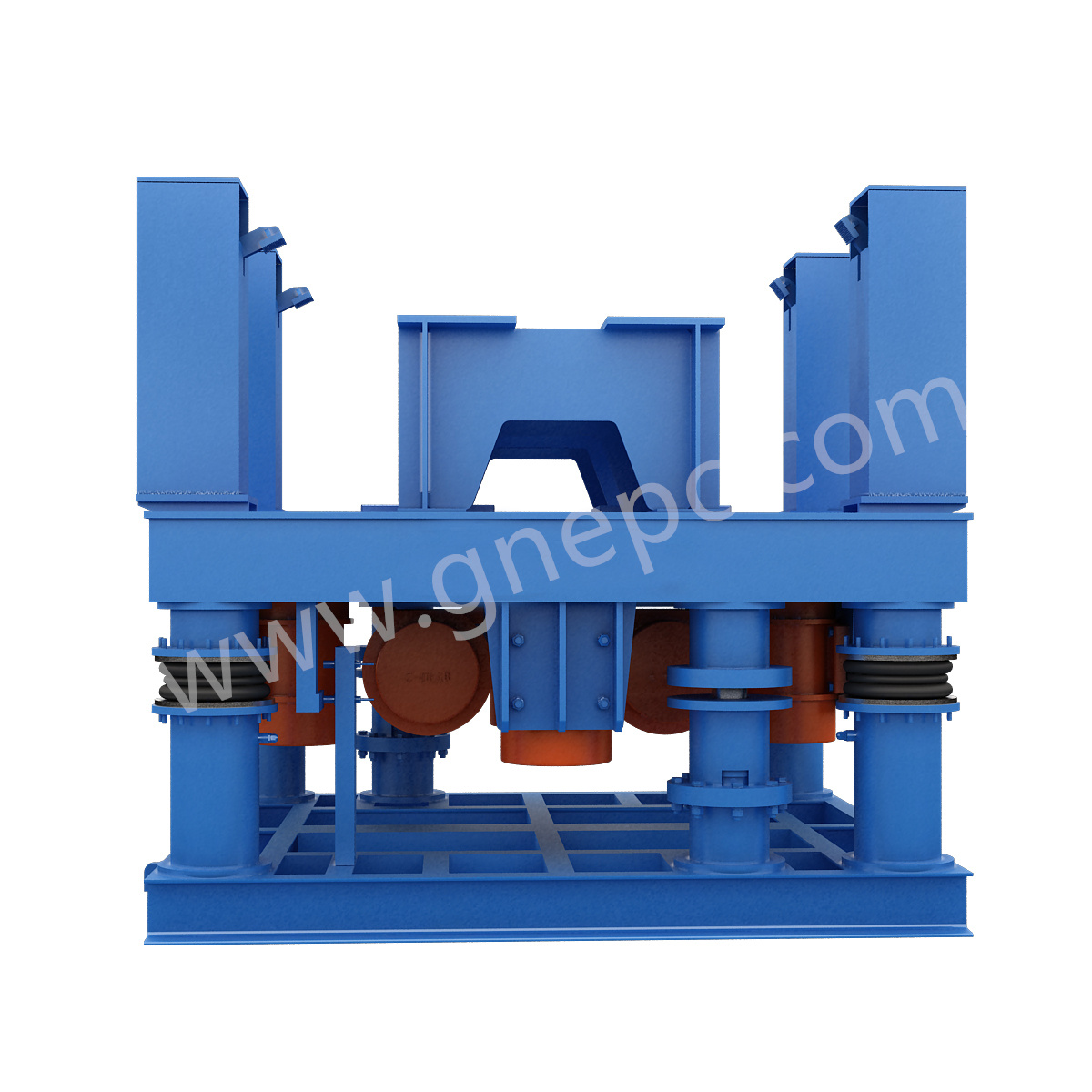

Permanent magnet servo vibration motor and its drive control system: it is composed of one main motor and three slave motors, which are distributed on two sides of the shaking platform, Total excitation force 0-120KN.Seismic strength: the seismic strength is generated by the rotation of the eccentric block of 4 vibration motors. The size of the seismic strength is mainly adjusted by choosing different vibration frequencies (0-3600 RPM) to change the vibration acceleration;

Plate thickness: the main structure of 20/16 mm steel plate welding molding .Hydraulic cylinder clamping, air bag jacking

Model MVE3200/3N-PM-75A0 exciting force 30KN, power 3.5KW

Rated speed 0-3600 RPM, frequency conversion control; IP65 protection level.

Integrated high-vibration position encoder, allowing operating temperature range -55°C~+155°C;

Stator embedded PTC or KTY84 temperature sensor;

With multiple pieces of high precision eccentric block, adjustable;

The use of eccentric block self-cooling, the maximum temperature of the motor < 65°C:

The main function and advantages

1)Function: it is mainly used for molding vibrating sand in production line design. Pid (proportion), integral (integral), differential (differential) control system is used to correct the system after making correct measurement and comparison.

2)Four independent permanent magnet servo vibration motors and their driving control systems. Each motor is independently controlled for “ Dynamic ” phase and speed adjustment. A particular combination of motor phases can produce many different desired vibrations. The servo vibration motor and its drive and control system have the following characteristics: the control speed is very fast, it takes 0.7 seconds from starting to rated speed, the starting torque is big, it can drive the eccentric block with large inertia to move, High power density and high operating efficiency; can support low-speed long-time operation; power off without rotation phenomenon, can be quickly controlled to stop action.

3 Each seismological cycle of the seismological station is driven by the seismological formula, We can design the specific seismological formula for the product according to the structural characteristics of the product. We can design many different formulas, each recipe can design up to multiple step areas.