Air-Cooled Water-Cooled Horizontal Cooling Machine

description2

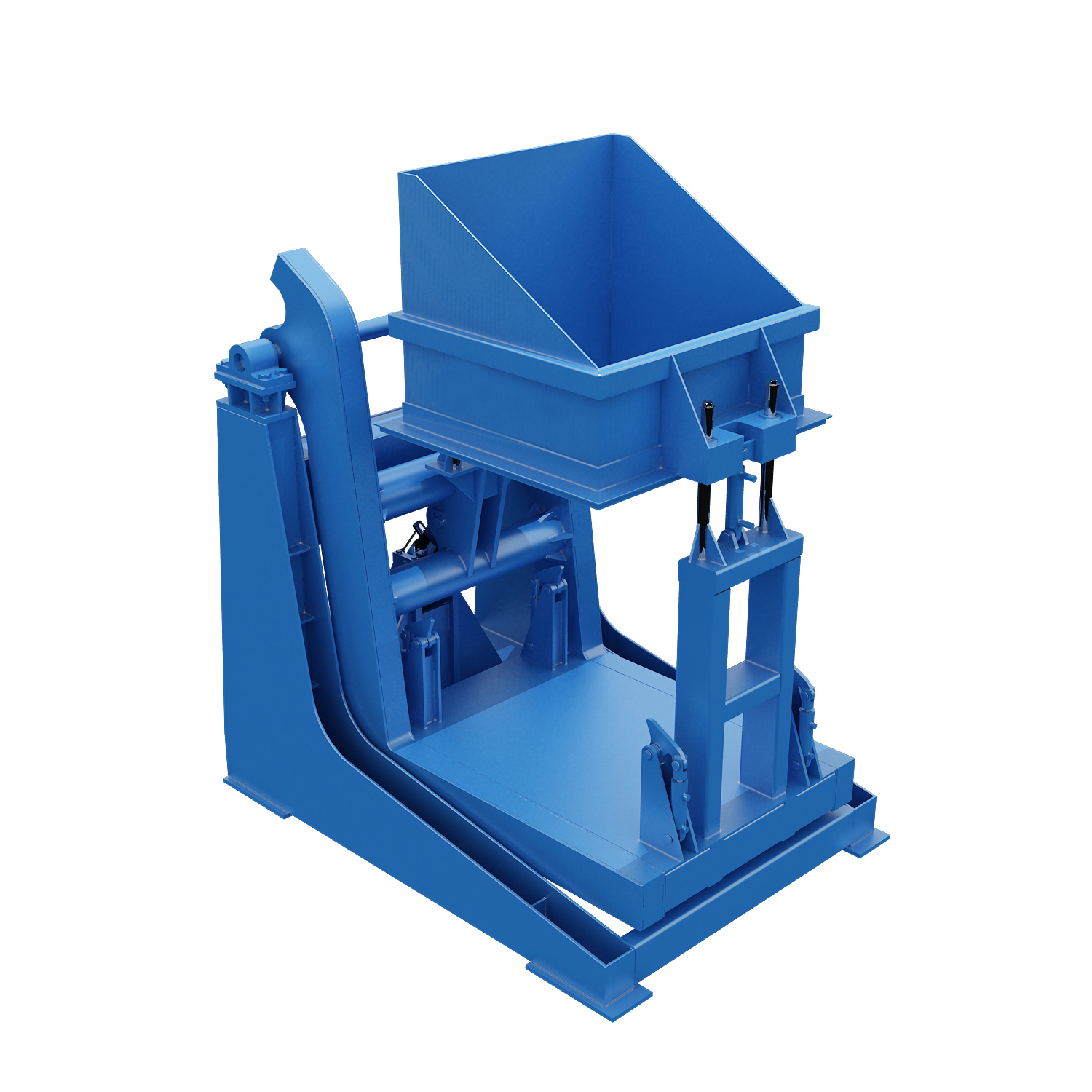

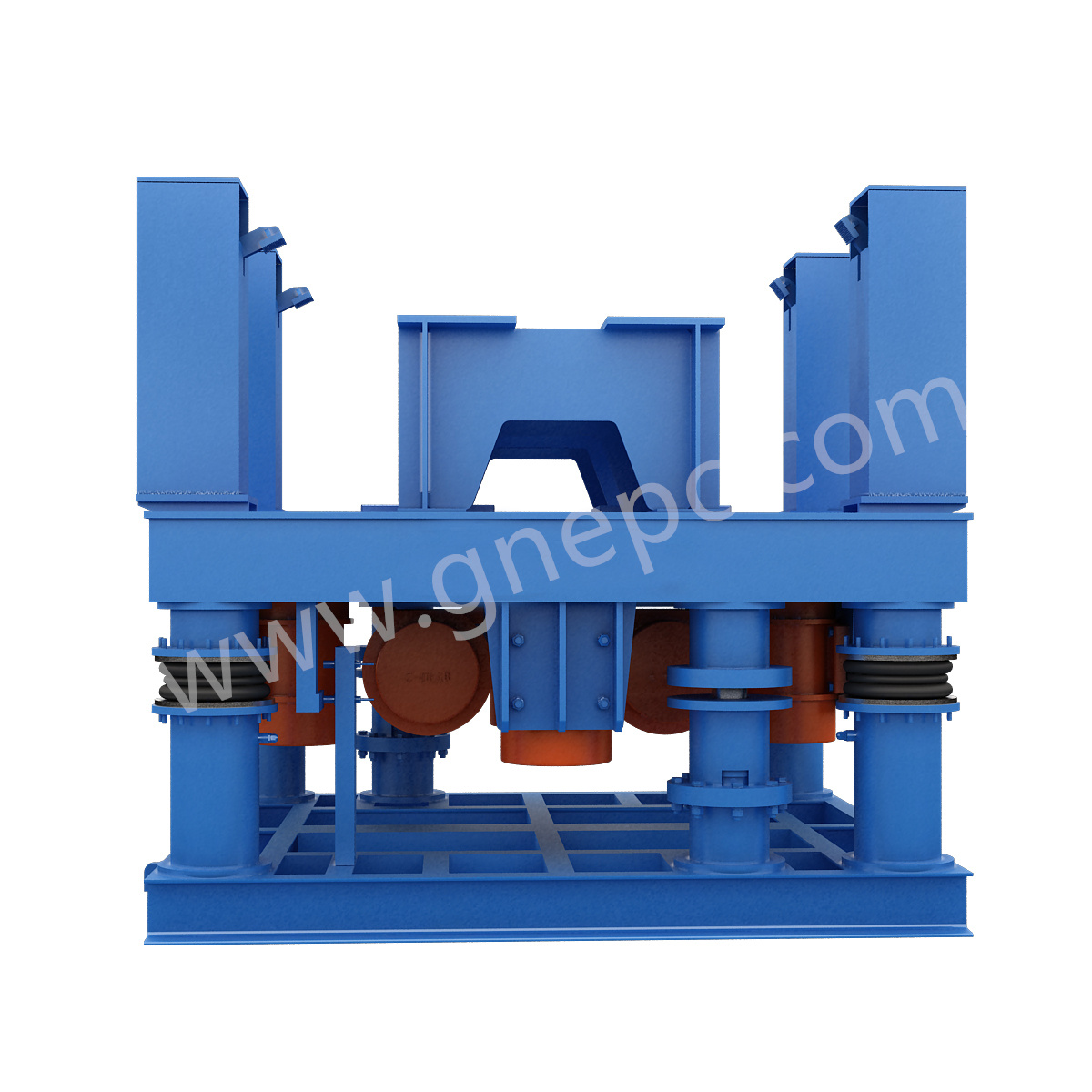

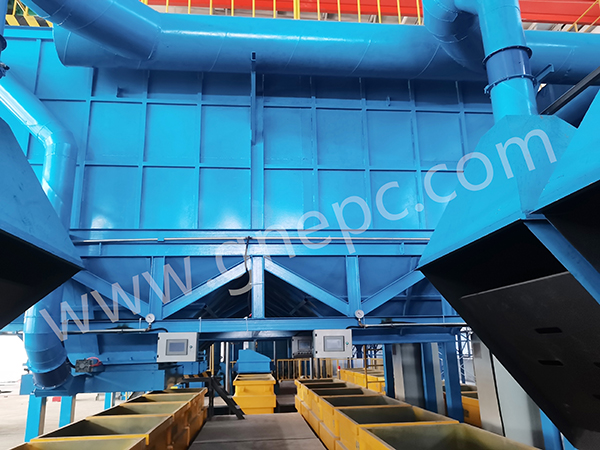

product display

Main technical parameters

- Overall dimensions: 8200*2000*2250mm;

- Power requirements: AC power with a rated frequency of 50Hz and a rated voltage of 380V (deviation ± 5%);

- Power: 15KW+0.75KW ×1;

- Shell steel plate thickness: 4mm, 10mm Bottom channel steel: 20 # channel steel;

- Transmission method: gear transmission;

- The bearing seat is made of cast steel to enhance strength;

- Conveying capacity: ≥ 7.5m ³/ h (20-40 quartz sand or pearl sand);

- Drum speed: Drum speed: 5-15r/min

- Cooling water consumption: 50-100 m ³/ h;

- Fan model: SF NO4-4; Air volume: 9300m3/h; Power: 0.75KW.

Product structure

- Horizontal cooling outer box: one set;

- Horizontal cooling inner drum: one set;

- Gear drive;

- Drive device: one set;

- Water-cooling system.

Product performance and working principle

The cylinder is composed of δ 9 spiral steel pipe is equipped with multiple spiral lines inside, and the drum is installed on the channel steel frame. To prevent the axial force during the operation of the cylinder, a pair of blocking wheel devices are installed to ensure safety. The molding sand enters the drum body from the feeding hopper, and due to the rotation of the drum body and the action of the spiral line, it self transports and lifts the material. The axial flow fan supplies air from the sand outlet direction to the drum body, and the hot steam is purified from the upper exhaust port of the feed hood at the front end through a cyclone dust collector before being discharged. The outer part of the drum is sprayed with water pipes to cool both inside and outside the drum.

Dust removal: This machine is equipped with a dust removal port and connecting flange on the upper part of the screening assembly, and an axial flow fan is installed at the sand outlet. The axial flow fan cools the hot sand, and at the same time, the dust gas is led out of the room through a dust removal pipeline with the dust collector. After the dust is removed by the dust collector, it is discharged from the chimney.