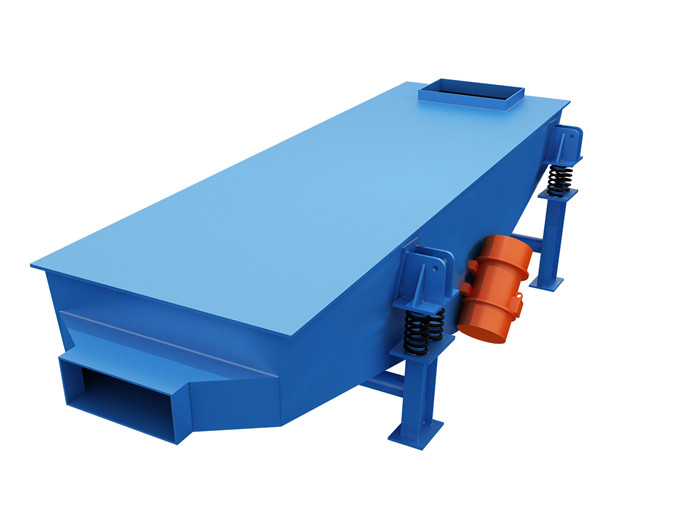

Zoo tshuaj ntsuam xyuas conveyor

piav 2

khoom tso saib

Main technical parameters

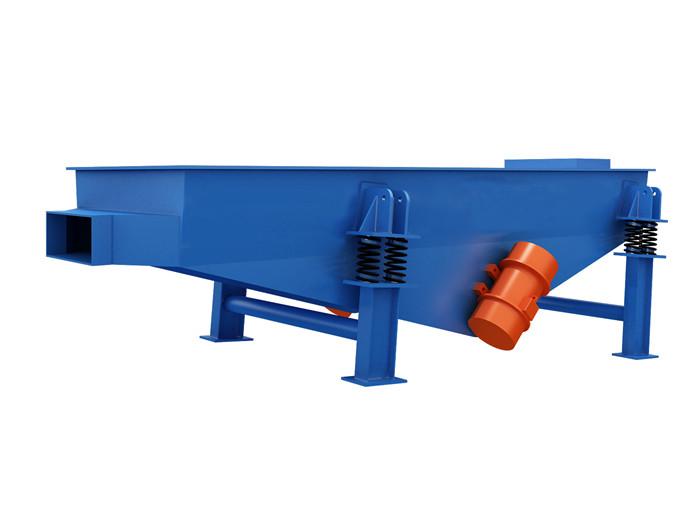

- Xuab zeb ua muaj peev xwm 60T / H (20-40 mesh quartz xuab zeb);

- Zuag qhia tag nrho qhov ntev: 2000 × 1100 × 1000 / 3200 / 4000 × 1000 × 1000 / 4000 × 1300 × 1200 / 4000 × 1500 × 1200mm;

- Cov khoom siv fais fab: 3KW * 2;

- Sieve phaj khoom: stainless hlau (thav duab 304 stainless hlau);

- Sieve phaj mesh: 50 mesh (zoo screen).

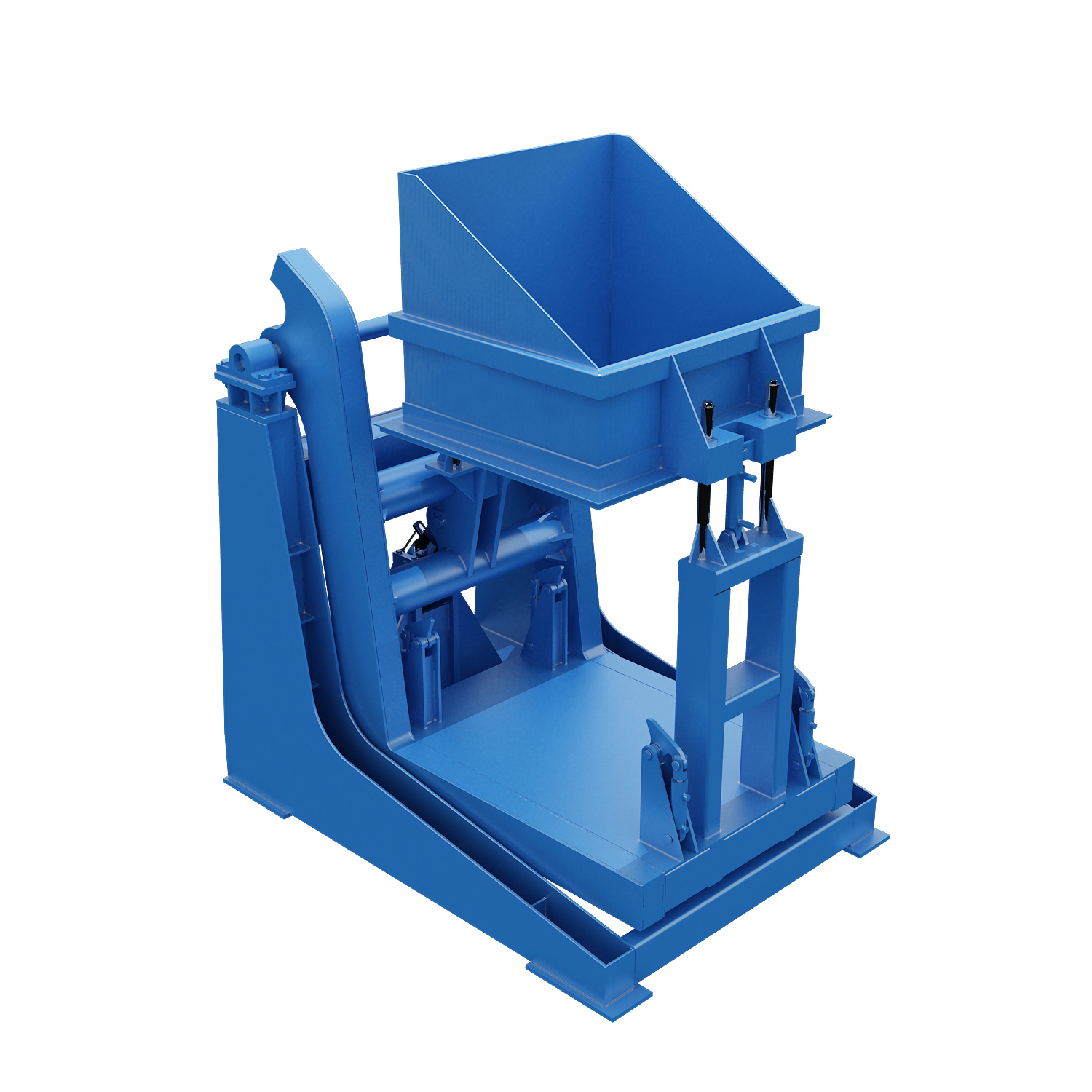

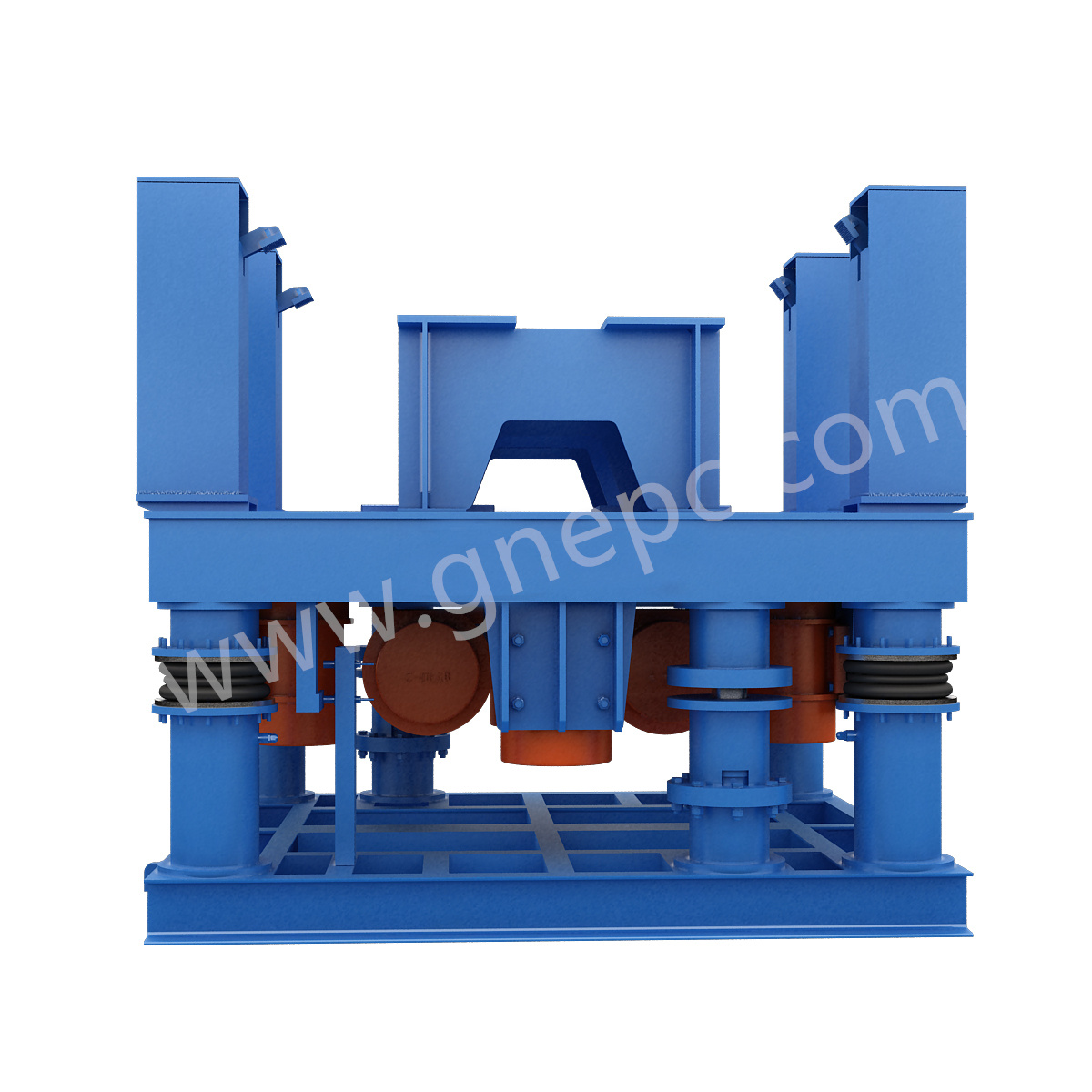

Khoom qauv

Kev tshuaj ntsuam xyuas conveyor muaj lub cev loj, lub hauv paus, thiab lub caij nplooj ntoos hlav ntawm kev tshuaj ntsuam conveyor (Φ 90 * 110). Vibration motor muaj pes tsawg leeg.

Main functions thiab zoo

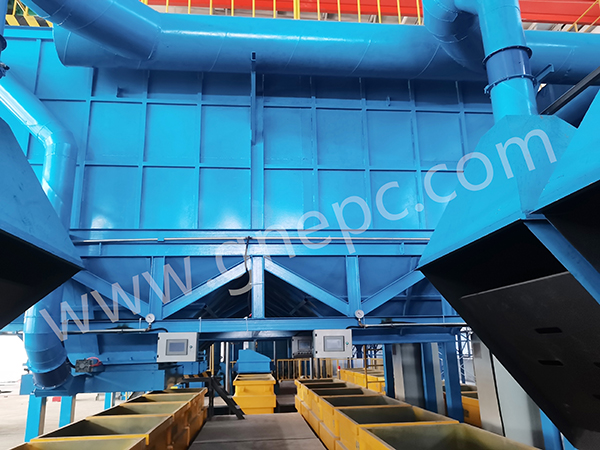

Kev tshuaj ntsuam thiab kev ua haujlwm: Kev tshuaj xyuas cov khoom siv yog siv los tshuaj xyuas cov hmoov hauv cov xuab zeb qub.

Kev ua haujlwm txias: Cov khoom siv sieve muaj txoj kab ntev ntws, uas tuaj yeem txo qhov kub thiab txias ntawm cov xuab zeb molding. Nws yog cov khoom siv txuag hluav taws xob thiab txuag hluav taws xob tsim los ntawm peb lub Hoobkas tshwj xeeb rau kev tsim cov xuab zeb qhuav tsis zoo siab casting.

Nws muaj cov yam ntxwv ntawm cov qauv txhim khu kev qha, muaj zog excitation quab yuam, kev tshuaj ntsuam xyuas kev ua haujlwm siab, tsis tshua muaj suab nrov, kev ua haujlwm ntev, kev saib xyuas yooj yim, thiab kev siv nyab xeeb.